DEVELOPMENT IS OUR STARTING POINT

Development and growth for clients and technical talent

Develop together

At Stanstechniek, we go beyond simply producing according to supplied drawings. We like to think with you and together come up with a design in which functionality is central and our knowledge of production is included. This leads to a design in which functionality, required quality and smart deployment of the production environment lead to the lowest possible cost. By cooperating intensively and investing in customer-specific knowledge and the necessary production resources, Stanstechniek offers new opportunities to develop in the market as a manufacturing company.

Knowledge central

Stanstechniek’s most important production factor is knowledge. The development and effective sharing of knowledge is central to everything we do. This keeps us ahead of the curve and allows us to offer customers an edge. This gives our professionals ample room to develop in disciplines and professional specialties. With problem-solving ability, courage and ownership, they give hands and feet to all the knowledge at Stanstechniek.

Co-engineering for optimized production

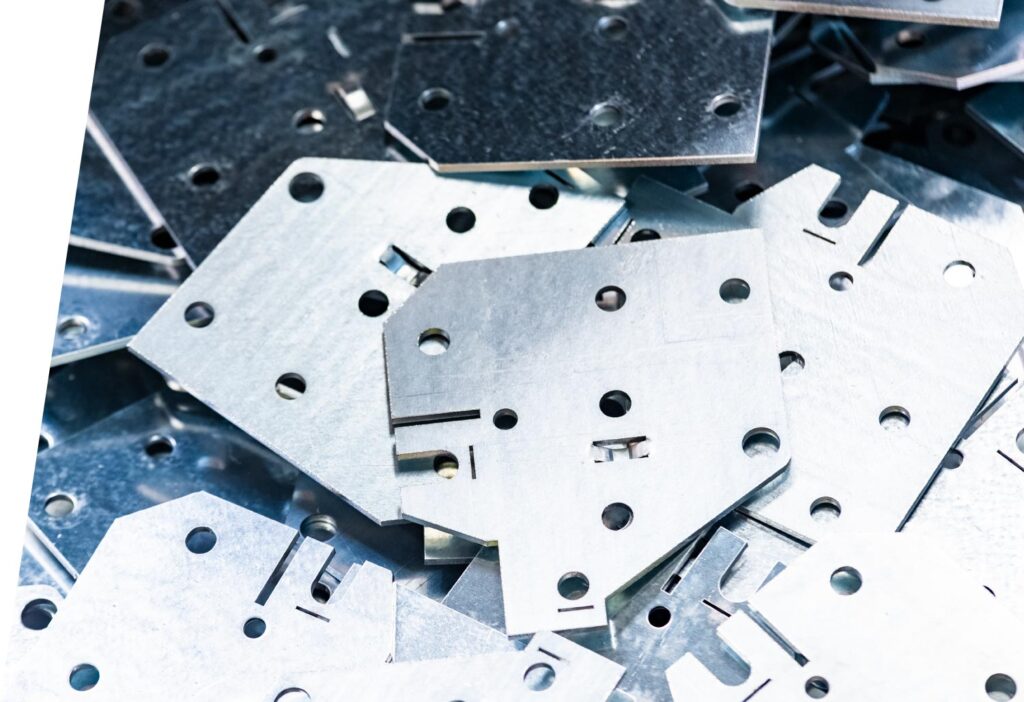

For both stamping and sheet metal, we can achieve cost savings and shorter lead times with co-engineering. For example, by thinking in modules, which in turn are made up of as few parts as possible. Or by using design studies to reduce plate thickness and save on assembly where possible. By having our engineers take a critical look at existing products as well, there is often much to gain in production speed, lead time or cost.

Two development and production routes

In order to best utilize all the knowledge and resources of the various disciplines at Stanstechniek, there are two main routes through which production takes place. For mass production and mass assembly of accurate stampings, your production follows the stages of the stamping route. For tight sheet metal work with our automated sheet metal plant, your order follows the sheet metal route.

Customer case study

optimization esdec clickfit evo mounting system

Tens of millions of units have since been delivered, but it started in late 2015 when Esdec, a specialist in mounting systems, asked us to work together to look at a more efficient implementation of a whole range of mounting hooks for their ClickFit Evo system that allows quick and solid installation of solar panels. From no less than 17 variants, we went to just one universal, adjustable and weatherproof version. And that too at less than half the original unit price.

Among others, we work together with